Fleet Camera and Video Features Explained

There are many exciting fleet camera or video solution options out there, from live streaming and on-demand video, to infrared and ADAS. The best-fit camera for your fleet doesn’t need to have all the features — just the ones that meet your specific needs. To help you determine which ones are best for your fleet, we’ve decoded some of the more important features. Do keep in mind that to get maximum value from the camera or video solution, the technology requires connectivity, storage and management.

360-Degree View

A camera solution with a 360-degree view will have multiple camera options to cover all sides of the vehicle (road-facing, rear-facing, side-mounted), as well as inside the truck cab (cabin-facing or driver-facing).

AI Camera

Artificial intelligence (AI) is used in some video solutions to automatically analyze video content for unsafe driving behavior. In cameras where the AI is embedded in the camera or recorder device, it can be used to audibly coach the driver in real-time for instances of tailgating, roll-through stops, drowsiness, distraction and other unsafe conditions.

Continuous Video Capture

Continuous video capture means that the fleet dashcam is on and recording as long as the vehicle is in operation. A benefit of continuous recording is that the camera is on to record events whenever they occur.

Infrared

If you manage drivers who work at night, you might need a camera that works in the daylight and also when it’s dark. Cameras with infrared (IR) sensors, also called night vision, can record in the dark, providing video or images in black and white.

Live-Streaming

Live streaming allows the fleet manager to see what the cameras are viewing as it happens, in real-time, from any particular vehicle they choose. Live monitoring can be useful, for example in monitoring an emergency to gain situational awareness.

On-Demand Retrieval

On-demand is ideal for when you want video only related to a specific time, place or event. Video on-demand empowers carriers to wirelessly retrieve video footage in real-time to help mitigate risk.

Integrated with Telematics

Integrating cameras or video with telematics is a time-saver. You can avoid the hassle of jumping in and out of multiple software apps and instead have one central place for your data, tools and insights. All camera and ADAS solutions on the Geotab Marketplace integrate with MyGeotab, meaning you can view and manage video in your existing fleet dashboard.

What features should a fleet camera have?

From our experience, there is no one answer to this question. Let your main use case, such as driver risk management, notification of collision, or security guide your ultimate choice. Let us help you get the whole picture on your drivers and vehicles with video telematics by finding the right solution for you.

Tracking Providers with Diversified Hardware for Versatile Solutions

Installing cellular assisted GPS devices in road vehicles and heavy machinery has become a standardized process for different fleet tracking platforms. While this approach provides a cost effective and powerful tracking solution for fleets able to maintain consistently solid cellular network connectivity, it’s not applicable in case uses taking place indoors or outside a cellular network. A more diversified set of hardware that utilizes Bluetooth technology in tandem with cellular assisted GPS is required to track assets in these environments.

It’s easy to take for granted the incredible energy density that gasoline-fueled vehicles provide to power conventional GPS tracking devices, but tracking smaller assets that aren’t able to power a GPS device has been historically challenging because of the limitations of battery technology. Fortunately, product developers in recent years have been able to take advantage of improved battery technology as well as Bluetooth sensors to offer tracking solutions for assets that were impractical to track in the past.

Case Uses for Specialized Asset Tracking

Modern specialized asset tracking devices work by using long lasting batteries to track devices anywhere out in the field with cellular assisted GPS tracking and leveraging Bluetooth sensors to let users know where assets are at a fixed location: warehouse, works yard, etc.

This robust new tracking methodology is utilized by a variety of industries with case uses such as:

Tracking forklifts that operate in indoor and outdoor environments. Usually unachievable with traditional cellular assisted GPS due to a signal loss once the forklift is indoors. By installing Bluetooth readers throughout the operating environment, users can get the precise location of their forklifts or similar pieces of equipment at all times. This application is scalable for any size of operating environment.

Tracking small tools on and off job sites. In the past, this has been challenging because of technological limitations and the associated cost. Basic GPS solutions requiring telecom connectivity were limited to high value assets. Modern solutions using a fixed or mobile local area wireless network on site have proven useful to track these small tools in a cost-efficient manner; but these lack reliability when they are not within the coverage area or left on site without a temporary local network.

Having an asset tracking device that can create an ad hoc mesh network to localize any small asset without 5G/4G connectivity has been game changing for many businesses. Assets equipped with these specialized asset tracking devices that use a Bluetooth edition of the tracking devices, allow businesses to track all their tools at an optimal cost.

An added bonus: in the event that tools are left at a job site and can’t connect to the mesh or cell network, users can walk through the area using a Bluetooth proximity sensor on their mobile phone to determine if any tools have been left behind.

Getting basic on or off site location data for any type of asset. At times, this is all that some users require, and they don’t need all of the additional functionality and costs that come with traditional tracking solutions. An initial investment of Bluetooth sensors with much lower monthly costs provide a much better ROI for such cases compared to comprehensive GPS tracking solutions. Furthermore, this low-cost solution will work for assets being stored both outdoors and indoors.

Adaptable Tracking Services Under One Roof

Organizations that require diversified hardware for versatile tracking solutions often also require comprehensive fleet management as well. Advantage Asset Tracking has been providing core fleet management to a variety of private enterprise and government fleets for over a decade and has now joined forces with leading asset tracking provider AssetFlo to give its clients adaptable tracking services under one integrated roof. We’ve discussed some of the more common case uses for this exciting new technology in this blog post. There are many more potential case uses for using combined cellular assisted and Bluetooth tracking devices depending on the requirements of the organization at hand.

If your business requires diversified tracking technology to facilitate its fleet and asset management, we welcome the opportunity to learn more about you and discuss how our services could help revolutionize your operational practices.

Blog post was written by Paul Edworthy. He can be reached at: paul@advtracking.net

Why You Need True Engine Diagnostics

Which is better: diagnostic or non-diagnostic GPS tracking? You may have heard about the benefits of each but the right answer for you may boil down to the details. Here is the difference between diagnostic and non-diagnostic tracking for fleet vehicles you need to know.

Diagnostic vs. Non-Diagnostic GPS Tracking

Diagnostic Fleet Tracking with an OBD-connected telematics device will give you critical engine data from the vehicle, including fuel usage and fill-ups, engine diagnostics, and engine faults (DTCs), plus seat belt, real odometer, and accurate idling.

Examples of data collected* with diagnostic tracking:

-

Actual Odometer from engine

-

Actual Engine hours from engine

-

Check Engine light on

-

Engine faults (fault code data)

-

RPM

-

Seat belt use

-

Fuel level

-

Total fuel used and Total fuel used when idling

-

Coolant temperature

-

Ignition detect

-

True idling

*Recorded if supported by vehicle.

Having access to engine diagnostics benefits a company in several important ways. First, by tracking fuel efficiency and idling, you can reduce fuel costs. Next, by monitoring engine faults, you can detect and respond to problems early, before they lead to costly downtime or potential safety issues.

Non-diagnostic is when the GPS tracking device is not plugged into the on-board diagnostics (OBD) port of the vehicle. The device could be connected directly to the vehicle battery and track movement by means of a GPS receiver.

What you get from non-diagnostic:

-

Basic GPS location

-

Speed

-

Acceleration

-

Geofence monitoring

With non-diagnostic GPS tracking, you can track trip progress and other basic details.

What You’re Missing with Non-Diagnostic

Non-diagnostics requires you to rely on drivers to phone in when the engine light comes on. But what if they get too busy and forget to report? Unreported issues with your engine means you could be putting unnecessary wear and tear on the vehicle, leading to higher repair costs later on — and could also cause a safety concern.

A telematics system with support for remote diagnostics, like Geotab, will send you an alert when an engine fault occurs, along with a detailed report, recommended actions, and nearest service location. When you’re looking at diagnostic and non-diagnostic fleet tracking systems, it really comes down to data accuracy.

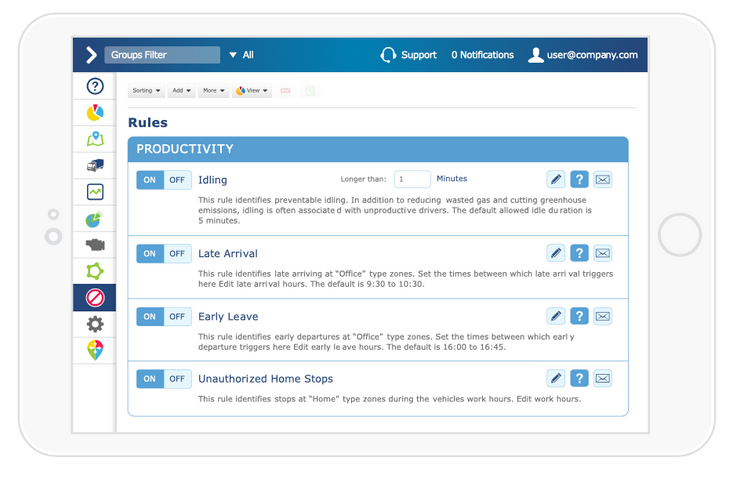

Idling and True Idling

Idling from a GPS perspective is adequate. It will tell you that the vehicle is sitting in place. However, in some cases, there could be outside forces affecting the battery. So, you won’t get a real look into true idleness.

In the diagnostic scenario, you can use the spectrum of data to determine whether vehicles are actually wasting fuel and time or if they are being used at a job site but just not moving. By combining RPM with the other data, you can actually see that the vehicle is idling. In addition, you’d be able to separate true idling from operational idling (e.g. cranes, vocational vehicles, or truck connected to a pressure washer in use, etc.).

From a business perspective, measuring idling accurately means you can target those costly cases of true idling that are impacting profitability.

Conclusion: Seek Rich, Quality Data

Bottom line, accurate readings can’t be taken from a vehicle’s engine without an OBD connection. This means that you’re missing out on valuable information such as engine faults, RPM, seat belt use, fuel level, coolant temperature, and more.

Having access to vehicle engine data can help reduce the likelihood of an accident or breakdown, saving money and possibly lives in the process. Although GPS data is useful and important, an OBD connection to a vehicle is imperative to get the full benefits of what the vehicle itself is able to give you.

The takeaway is that for fleet management, it’s important to choose a platform that collects both diagnostic and non-diagnostic data. Without the engine diagnostics, you really don’t have visibility of what’s going on in the vehicle.

Why are sustainability and electrification priorities to fleet managers?

The challenge of reducing the environmental impact of the transportation industry has been worked on over the last few decades. In early 2020, it became more of a focus, particularly with battery electric vehicles (BEVs). This change has been driven by significant improvements in battery technology and an overall reduction in cost. Combined with new governmental emission mandates, funding initiatives and public demand for zero-emission technologies, the stage has been set for BEVs to dominate the transportation industry.

Fully electric vehicles currently represent the most positive outcome. With zero tailpipe emissions, they have a much smaller impact on the environment on average and as renewable energy continues to improve it will only get better. EVs also present fleets with the opportunity to improve their bottom line. Since the cost per kWh of electricity and maintenance costs are cheaper compared to the equivalent expenditures for operating ICE vehicles, electric vehicles typically have a much lower total cost of ownership.

At Advantage Asset Tracking, we have noted that many fleets are choosing to electrify for more reasons than just meeting emission mandates. Guided by a sense of social responsibility, financial incentives or both, many of the organizations we work with have created their own sustainability goals and a roadmap to achieving those goals.

How to go electric

According to GNA’s State of Sustainable Fleets survey, 69% of responding fleets, who are early adopters of clean vehicles in the U.S., planned to either pilot or purchase a BEV in the next 12 months. There are a number of steps to take when adopting BEVs, like contacting your electric utility company, but the first task is determining where it makes sense to electrify and that’s where we can step in and help.

Geotab offers a complimentary EV Suitability Assessment (EVSA) to determine which ICE vehicles in your fleet can be replaced with an electric model while maintaining operations and reducing costs. We encourage fleets to run these assessments, which are based on fleet-specific data, on a regular basis. In doing so, fleets can re-evaluate the electrification potential following duty cycle changes or as new incentives and vehicle models become available.

The idea of transitioning your entire fleet can seem like a monumental task, but we feel fleet electrification should be viewed as a gradual process. By replacing a small number of vehicles at a time a fleet can essentially test the water and begin to optimize their operations before a large-scale adoption plan.

Telematics is the key to optimizing EV operations

Once you have incorporated electric vehicles into your fleet there are steps you can take in order to increase the benefits of your investment. The key to unlocking this knowledge is by reviewing your telematics data.

Through data-driven insights, fleet managers can optimize routes to ensure the vehicles can cover the most miles without needing to charge en route. They can also establish best practices for charging and driving habits to maintain the vehicle’s battery health and improve range.

Maximizing the efficiency of the vehicles in your fleet is nothing new and many of the same techniques will still apply for BEVs. By using fleet management software that allows you to manage both ICE vehicles and BEVs within the same platform, you can streamline the entire process.

The state of sustainable fleets

Fleet sustainability is beginning to blossom across different clean fuel technologies. Current electric vehicles are range capable and can operate at a lower operational cost over their service life for the majority of fleet vehicle duty cycles. As more electric vehicles enter the market in new vehicle classes such as pickups, medium-duty and so on, fleet managers equipped with the right data and tools will be able to assign the right vehicle to the right job and seamlessly integrate the operations of electric assets with vehicles.

In order to stay ahead of the curve, we encourage fleet managers to contact us to support and educate in all of the tools available to them. After all, some of the upcoming government mandates around the globe are only one to two service lifecycles away.

How Telematics Can Help Fleet Managers Navigate the Semiconductor Shortage

Modern-day automotive vehicles are increasingly relying on advanced technology to deliver an exceptional driving experience along with innovative safety and mobility features. But with the unprecedented global semiconductor chip shortage currently taking place, nearly every industry, including businesses and government agencies dependent on the technology for their fleets’ everyday operations, is really feeling the pain.

One way the shortage is due to seriously impact business and government fleets is by restricting availability of new vehicles until supplies bounce back. For government agencies alone, this creates a real problem as the 1.2 million vehicles in operation since the end of 2019 will likely need to be replaced in the coming months.

What the Shortage Means to Vehicle Replacement Cycles

Because of the shutdown, fleet orders for the 2021 model year have been cut off much earlier than normal. As a result, businesses and government agencies that are currently looking to replace or add vehicles to their fleets are finding it increasingly difficult to do so.

While fleet managers may want to consider waiting until the 2022 model year to replace their vehicles, the threat of production constraints will continue to exist unless the chip shortage situation improves.

As managers wait for new vehicles to become available, they will find themselves forced to extend the service life of existing vehicles until the shortage has been resolved. Necessary maintenance is likely to become mandatory to ensure fleets are able to continue running safely throughout the upcoming winter months without any interruption.

Using Telematics to Improve Maintenance

While the maintenance needed to get a vehicle back on the road can be expensive, every fleet manager knows its importance especially if it means preventing or delaying a vehicle’s replacement. Fortunately, a telematics solution can help keep fleets in ideal shape, as well as take away some of the monitoring and reporting burdens from drivers. Geotoab’s telematics solution provides raw fault data pulled from its API platform and translates it into detailed instructions. This makes it easier to understand faults and help prioritize repairs. Many areas inspected regularly include, but are not limited to, brakes, tires, windshield, battery life, air filter, and fluids.

Advanced fleet management software that is equipped with GPS tracking technology can also monitor fuel usage and mileage. This type of monitoring can indicate how long a vehicle has been operating and will alert fleet managers when maintenance is needed or upcoming. Using data as a guide helps boost productivity and serves as a warning system before maintenance issues become a real problem. Not only does telematics help improve vehicle health, it also improves the accuracy of preventive maintenance, resulting in lower costs down the road.

Beyond its safety related benefits, video telematics can provide fleet managers with data and insights needed to identify habits or issues that may affect the maintenance of their vehicles. Risky driving behaviors can increase wear-and-tear on a vehicle, including accelerating too quickly, hard braking, speeding, or hitting curbs. By identifying and then reducing these types of behaviors, fleets can increase the longevity of their brakes, transmissions, tires, and suspension parts. Ultimately, telematics solutions can make a big difference in overall maintenance efforts at a time where vehicle replacement is becoming more of a challenge.

Making Telematics Work for You

When first implementing telematics to enhance a company’s fleet maintenance efforts, some fleet managers may face challenges they should account for so no time is lost while getting the system to work for them.

One of these challenges is a lack of knowledge and understanding of the data provided. Having access to data can be helpful but only if you know how to utilize it properly. Under these circumstances, it becomes critical for managers to work closely with their telematics providers who will make sure they maximize their fleet data by offering the support needed to understand how to best utilize it to improve their fleet’s efforts.